Abstract

Recently the emergence of a new generation of infrared sensors – the microbolometer technology – based on an

infrared thermal detection mechanism which is particularly suited to operate at ambient temperature has opened the

opportunity for achieving low cost infrared imaging systems for both military and commercial applications. In a first

part, this paper gives an overview of this challenging technology highlighting the main characteristics of the sensors

developed by LETI that are particularly relevant to automotive applications. A special highlight on recent results

concerning the 160x120 focal plane array with a pixel pitch of 35μm is given. In a second part, the use of this

technology in automotive safety field is illustrated through an application of detection of moving objects in front of

a vehicle. The results shows that infrared sensors based on well-designed microbolometers represent a real middleterm

alternative to usual video sensors.

1. Background

The automotive industry increasingly looks to Microsystems to put intelligence into cars. Safety improvement is

particularly concerned with this trend: acceleration sensors for airbags, tire pressure monitoring and collision

avoidance radar system. However, despite all of the automotive safety breakthroughs of this last decade, drivers still

face potential hazards during conditions of darkness or obscured visibility such as is present with fog, heavy rain or

snow. A challenging concern for the next few years is to improve vehicle safety in such adverse conditions with the

operation of front-hazard warning devices and reliable collision avoidance systems.

One of the major issues of such safety systems largely deals with the availability of adequate sensors that allow an

early and reliable detection of road obstacles in front of the car. Infrared thermal imaging is particularly suited for

this purpose as it provides an effective night-time viewing system that could tackle the inefficiency of the usual

sensors and fulfils the night driving safety requirements. Indeed, thermal imaging systems detect the

electromagnetic radiation emitted by any object at room temperature whatever its natural or artificial illumination.

As a result, infrared sensor intrinsically offers large advantages in comparison to alternative sensors working in the

visible spectrum or in the millimetric wavelength range such as radars do. This statement is clearly illustrated

considering that a visible vision camera exhibits poor efficiency in bad weather conditions even if it is coupled with

automobile headlights illumination. Moreover the range of the road that can be covered by headlights at night is

much less than the eye can see during daylight. Unlike visible vision, Infrared vision enhances the range of visibility

at night up to six times further than standard headlights. On the other hand, radar systems typically have poor

resolution because of their long wavelength. Consequently radar gives limited information regarding the shape of

the detected object in comparison to infrared imaging.

For various technological and financial reasons, infrared imaging has been primarily developed for military

applications. Such systems were originally based on quantum devices that typically operate at liquid nitrogen

temperature [1]. This low temperature requirement leads to high cost systems and has dramatically restricted the use

of thermal imaging. But recently the emergence of a new generation of sensors – the microbolometer technology –

based on an infrared thermal detection mechanism which is particularly suited to operate at ambient temperature has

opened the opportunity for achieving low cost infrared imaging systems for both military and commercial

applicationsIn this context, CEA/LETI has been involved in amorphous silicon uncooled microbolometer development since

1992 [3]. This high performance infrared technology is now commercialized in mass production by the French

company ULIS and it will rapidly meet the market ramping up demands like car safety applications. In order to

prepare the next infrared launch into automotive industry, CEA/LETI is involved in two European projects that aim

at improving automotive safety. In EURIMUS framework, a project named ICAR is under progress to develop a

specific camera for an affordable Driver Vision Enhancement (DVE) systems [4]. Besides, the SAVE-U project,

partially funded by the European Commission INFSO DG under IST program aims to develop an enhanced

vulnerable road users (VRU) detection system based on several detectors : a 24 GHz radar network coupled with a

vision part composed of both visible and infrared imaging sensors [5].

In a first part, this paper gives an overview of microbolometer technology highlighting the main characteristics of

these sensors that are particularly relevant to automotive applications. Then the paper will focus on recent results

obtained from a 160x120 microbolometer infrared focal plane array (IRFPA) with a pixel pitch of 35μm that has

been specifically designed for automotive Driver Vision Enhancement in the scope of ICAR project. In a second

part, the use of this technology in automotive safety field is illustrated through an application of detection of moving

objects in front of a vehicle highlighting the potential of this technology for pedestrian detection in the context of the

SAVE-U project.

2. Microbolometer development at CEA/LETI

2.1. Thermal detector structure

The schematic structure of an uncooled thermal detector is shown in figure 1. As a general rule, these detectors

measure the temperature rise due to IR radiation absorption by a thermally insulated element. For this purpose,

thermal detectors are mainly composed of an infrared absorber embedded in closed contact with a thermometer

element. The thermometer element senses incoming IR induced temperature rise and converts it into an electric

signal. The most common detection mechanism is the resistive bolometer whose resistance changes with

temperature, but various other mechanisms can be used, such as pyroelectric effect [6, 7], thermoelectric junction

[8], P-N junction conductivity [9] or thermal stress induced mechanical deflection [10]. Considering a two

dimensional array of detectors, a readout integrated circuit (ROIC) is generally designed to measure the resistance of

each bolometer and to format the results into a single data stream for video imaging purpose. Finally, due to the

strong correlation between thermal insulation and sensitivity, the high performance uncooled IR detector must be

operated under vacuum – typically 10In the footsteps of MEMS devices, microbolometer sensors have taken benefits from the latest silicon technology

advances. Unique surface micromachining techniques have been developed at CEA/LETI in order to produce above

the full custom CMOS readout circuit, very thin membranes made from amorphous silicon that are very sensitive to

infrared incoming radiations heating. Figure 2 shows schematically the structure of such a pixel whereas figure 3

describes its manufacturing process flow.In a first step a thin aluminium reflective layer is deposited and delineated directly on top of the ROIC. A 2.5 μm

thick polyimide sacrificial layer is then spun and cured. An amorphous silicon film 0.1 μm thick is deposited over

the polyimide layer and covered by a metallic electrode obtained by reactive physical vapor deposition. Vias are

opened by dry etching throughout the structure down to the ROIC pads, and metal deposition and etching achieves

electrical continuity between the underlying substrate and active bolometric structures at the surface of polyimide.

At this point electrode delineation is done by wet etching of the metallic film selectively over the amorphous silicon.

The pixel contour is delineated and dry etched to the polyimide, and a final local polyimide etch over testing pads is

carried out. At this stage the wafers are tested for standard automatic electrical functionality and acquisition of array

parameters. Finally the microbridge arrays are created by polyimide removal in conventional resist etching

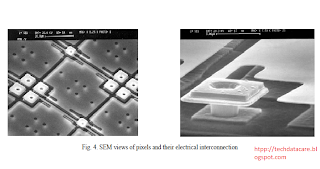

equipment. Figure 4 shows scanning electron microscopy pictures of a pixel and the detail of the metallic stud that

interconnect the microbolometer detector to the ROIC through the thermal insulation leg.On this technological baseline, a first generation of bolometer technology focused on 45μm pitch was developed

and transferred to ULIS in early 2000 [11]. ULIS is currently manufacturing and commercialising two different

products (figure 5) based on a 320x240 focal plane array. These are both packaged under vacuum in a metallic

package. The UL01 01 1 device is a general purpose imaging uncooled infrared array whereas UL01 02 1 E device,

as it is supplied with an extra internal thermal shield, is more suited for radiometric applications. 2.3. Cost reduction studies

The requirements of automotive application like the Driver Vision Enhancement system is mainly constrained by

objective cost of the overall system. CEA/LETI and ULIS technology is particularly designed to meet these

requirements. In fact, one of the key point of CEA/LETI and ULIS microbolometer technology has been to elect a

thermometer material made from amorphous silicon that features absolute compatibility with standard silicon

processing. This basic option leads to a high yield monolithic arrangement fully compatible with commercially

available CMOS silicon wafers. This feature intrinsically guaranties low cost attainment ideally suited for large

market distribution. Nevertheless, to extend this low cost high volume approach even more some further

developments are under progress at CEA/LETI in partnership with ULIS. The main point consists in reducing the

pixel size. Another key point is to develop advanced packaging techniques as it is well stated that vacuum packaging

is a cost driver in MEMS devices and particularly in uncooled IRFPA. A third point is to increase the integration of

advanced functions on the focal plane in order to facilitate its integration into system equipments.

2.2. CEA/LETI technology

Cost reduction has multifold benefits from this pitch reduction approach. Obviously, owing to the increase of the

number of dies per wafer, this will reduce the cost of the bolometer array itself. Besides, given a processing defects

density, the manufacturing yield is directly linked with the focal plane array size. Furthermore, this size reduction

will impact on both the dimension of the bolometer packaging and the form factor of the camera and consequently

their cost. Finally, we can expect a dramatic drop of volume, weight and cost of the infrared optics as the diameters

of the lens are directly linked with the size of the pixel for a given field of view and optical aperture.

To maintain a high level of performance despite the decrease of the pixel size, CEA/LETI in partnership with ULIS

have engaged in deep technological developments for the last couple of years. These developments aims at

increasing the thermal insulation of the pixel and at reducing the 1/f noise. In order to address this issue, an

innovative second generation technological embodiment, totally compatible with the ULIS industrial process, has

been developed. This so called second generation amorphous silicon microbolometer technology exhibits

dramatically enhanced sensitivity and enables the decrease of pixel pitch to 35μm, keeping a level of performance

entirely compatible with automotive night vision requirements. This second generation technology is now

completely matured and will be transferred from CEA/LETI research line to ULIS production line in 2003.

It is well stated that thermal insulation is the most critical parameter defining the performance of uncooled detectors.

In order to improve this point, the microbolometer designer can rely on two different options.

A first option consists in increasing the length of thermal insulating legs that sustain the microbolometer above the

CMOS substrate. The main drawback of this approach is the damaging decrease of the fill factor of the detector

induced by the increase of the area devoted to the insulation legs implementation. A two level pixel arrangement has

been proposed to tackle this issue but at the cost of a more complex and costly manufacturing process [12].

A second option followed at CEA/LETI is to achieve an enhanced thermal insulation by an advantageous reduction

of the section of the thermal insulating legs. According to this option, the length of the legs are kept pretty the same,

resulting in both high thermal insulation and high fill factor high absorption features. CEA/LETI – ULIS second

generation microbolometer technology relies on this approach. Typical characteristics of this second generation

technology for a 35μm pixel pitch are summarized in table 1, whereas typical microbolometer absorption spectra

obtained from reflection experiments using an infrared integrating sphere are disclosed in figure 6. We can notice

from these experimental data that for a given pixel pitch of 35μm :

•

Thermal insulation (Rth) has been increased by a factor greater than 3.•

extra 60% 1/f noise reduction resulting from the optimization of the detector design (architecture improvement

of the pixel as well as technological design rules shrink).

Similarly, the NETD figure has been improved by a factor of 5 due to the previous Rth enhancement and to an•

video frame rate, it has been possible to increase R

35μm pixel pitch.

As far as the time constant (Tth) of the 1st generation technology exhibits a tremendous margin regarding usualth keeping a fully usable time constant close to 12 ms for a•

and high optical efficiency in the 8 to 14 μm wavelength range have been maintained as it can be noticed from

spectra of figure 6.2.5. Advanced readout development

Taking profit from the achievement and maturing of the second generation microbolometer technology ULIS and

CEA/LETI have designed a 160 x 120 2D arrays in the scope of ICAR project with particular attention to the low

cost automotive market. This new IRFPA is fed with a number of innovative on-chip features to simplify the use of

this focal plane keeping a very small silicon ROIC area down to 0.7 cm² for the 160 x 120 array, in order to reduce

wafer-level processing costs per die. This new 160 x 120 is designed to fulfil low resolution, low cost applications.

One of the most promising function is the possibility to adjust the skimming of the common mode current for each

pixel by an automatic acquisition and in-pixel storage of non uniformity coefficients in a first step and readout pixel

signal in a second step. At power on, the detector acquires its pixel compensation coefficients and stores them in onchip

memory for performing the current compensation during the following images acquisition and readout

sequences. This automatic mode of operation could be changed to an external driving mode with non uniformity

coefficients stored in an external memory (see figure7). The video output is available in analogic or digital format

with an on-chip 12 bits (2 x 6) ADC. Most of the biases are generated inside of the ROIC for friendly user

operatio2.6. Packaging development

Metallic package

Metallic packages belong to the first generation of package used to integrate the microbolometer chip (figure 5), but

their cost remains a large part of the total detector cost and this trend will be amplified in the near future as the pixel

pitch will be reduced. As a consequence a less expensive package technology would be welcome and various

developments are under progress in this field.

Ceramic package

Ceramic packages (figure 9) are currently developed at ULIS. This technology is using available technologies

developed for chips made in high volume production. Only the process used to assemble chip carrier and window

carrier is adapted to take into account the required greater than 10 year lifetime under vacuum. These package

constructions are compatible with automatic assembling machines that will contribute to decrease manufacturing

cost.

Wafer level packaging

Beside these rather standard packaging techniques, CEA / LETI is working on the development of a wafer level

packaging system in order to achieve the ultimate reduced manufacturing cost. This goal is completed in a 4 steps

process. First, thanks to bulk micromachining techniques, a silicon micro-chip carrier is prepared on a silicon wafer.

In a similar way, a second silicon wafer is processed in order to achieve an infrared window. These two substrates

mainly consist of cavities and metallic thin film rings used for interconnecting and welding purpose. Then,

individual microbolometer IRFPAs are positioned and wire bonded into each chip carrier cavity. Finally, the

collective assembly (welding process) of the two wafers is carried out under vacuum leading to microbolometer

IRFPAs shut under vacuum into silicon cavities. The major advantage of this technique in comparison to

competitive option studied elsewhere [13], is that it does not require any extra soldering area on microbolometer die

and consequently it contributes to IRFPAs cost reduction.

3. Application in the automotive safety

Traffic accidents are responsible for an unacceptable huge number of casualties all over the world. To improve this

situation from the technological point of view, vision based systems for automotive safety represent one of the most

promising development for driver assistance. But it is well known that in bad weather conditions, at night and

usually every time the visibility is reduced the number of accident is increasing. Infrared video sensors, because they

are not too much affected by such conditions, are well adapted to automotive applications. In the SAVE-U project, it

has been chosen to use an infrared video sensor in addition to a visible wavelength video sensor and a radar to cope

with difficult situations. The application reported in this paper was developed within the SAVE-U project. The

objective was to detect obstacles coming in front of the vehicle to perform in a later stage their classification, which

is not presented here. The final objective of SAVE-U is to develop a system able to protect vulnerable road users

(pedestrians and cyclists).

Many current traffic accidents happen when unpredictable changes occur in the vehicle vicinity, therefore one of the

main important task is to detect those changes. Looking at a scene taken by a camera mounted on a vehicle, it

appears that main changes are due to vehicle global motion while minor changes are rather related to other moving

objects such as cars, bicycles or pedestrians. If we then estimate the camera induced 2D motion field and use it to

align two successive images, regions with secondary motions will be badly corrected and easily detectable (as

illustrated below). The technique consists in estimating the camera motion and in finding regions whose motion is

not consistent to it. This approach is based on image compensation techniques.In the first section we will show how, using some restrictions, camera induced motion can be represented with a

polynomial model. In a second part we will present the regression criterion used to compute the model parameters.

As images present multiple motions simultaneously, the problem is reformulated in a robust framework such that

secondary motions correspond to non conform data (outliers). These regions are then rejected from computation

during the estimation process and will not corrupt the final solution. An iterative multi-resolution estimation scheme

is also used to cope with high motion and reduce noise influence. Finally results and conclusions are given in the

last section.

3.1 Camera motion model

In the real 3D world, the camera motion is described by two components: a translation

camera motion, a scene point P appears to be moving with rotation

P could be deduced from those remarks. After the modelling of the camera orientation and location, the projection

of the real scene on the 2D sensor plane can be modelled using a perspective projection [17] but it leads to an

expression of the 2D velocity field, which is not free from the Z-depth parameter always difficult to recover with a

single camera. To get rid of the Z parameter, it is assumed that the scene can be approximated by a plane:

T and a rotation Ω . Due to−Ωand translation − T . 3D velocity vector ofZ

Conclusion

This paper has put emphasis on the main features of CEA/LETI infrared microbolometer technology. One of the key

points has been to elect a sensitive material made from amorphous silicon that features absolute compatibility with

standard silicon processing. This basic option leads to high performance and low cost infrared imaging systems

particularly suited for large market distribution such as automotive applications. This technology is now

commercialised in mass production by the French company ULIS, while a brand new advanced technological

arrangement has been demonstrated at CEA/LETI. The advent of this second generation of the technology results in

a fivefold performance improvement compared to the current industrial process and NETD of 56 mK obtained from

35μm pitch, 160x120 IRFPA has been demonstrated.

The results of detection by image processing techniques on infrared video sequences indicate that the approach

gives better results compared to those obtained with images coming from video cameras working at visible

wavelength. One reason seems to be that IR images present less detail but they are nevertheless textured enough for

motion estimation. From that point they represent a very good alternative to visible wavelength sensors.= a X + bY + c (4) .Despite pitch reduction from 45 to 25μm and associated dramatic pixel area drop, fill factor larger than 80%

0 comments:

Post a Comment